Sale!

(If added to the unit add $149.00) These unloaders are built into the intake valve assembly on the compressor head. These unload or open the intake valves under constant run applications such as gas drive and electric units for constant run applications. This feature reduces internal pump heat from compression because the intake valve is held open under unloading cycle. It allows fresh air to come into the cylinder chamber but under compression stroke, the unloader holds the intake valve open allowing the air to blow back out the intake filter. This fresh air absorbs the heat out of the pump under heavy workloads. This pump includes a pre-cooling line that cools the air before it goes into the tank and also includes an all copper main feed line from the pump into the tank. This is copper for durability and not aluminum. We have one of the lowest RPM compressors on the market. This is critical. Many companies are lowering the quality of their product and running high RPM. High RPM causes high noise or db levels, lots of water in your air because the air is much hotter, lots of vibration and harmonic distortion, less belt wear, and most of all – longer pump life. Don’t cheat yourself…go low RPM and a BIG pump. Go Big or go home – you will be glad you did. Compare pump speeds from different manufacturers and you will see we are the lowest RPM. We can still give you high CFM with low RPM because our bore and stroke are larger allowing us to run the pump slower causing less friction and heat buildup. Just remember…speed kills. Our competition is using small pumps that are noisy and high RPM. This is a recipe for pump failure.

Original price was: $5,179.00.$4,699.00Current price is: $4,699.00.

Tech Questions

330.413.5262

BLAST CABINET 7.5 HP Compressor

Running HP: 7.5 HP

Voltage: 208-230 Volt AC

Phase: 1-Phase

Magnetic Starter: Yes

Pump

CFM @ 175 PSI: 35

Pressure oil feed

Max PSI: 175 PSI

Pump Material: Solid Cast Iron

Pump Type: Two-Stage

Continuous-Duty: (optional add $149)

Tank

Tank Size: 80 Gallons

Tank Outlet: 3/4 Inch

Tank Orientation: Vertical

Accessories

Auto Drain Valve:( Optional add $119)

Overview

Certification: UL/CSA/ASME

Dimensions: 33L x 24W x 73H

(83.82 x 60.96 x 185.42 cm)

Product Weight: 944 lbs (411.87 kilograms)

Consumer Warranty: 5 Years

Description

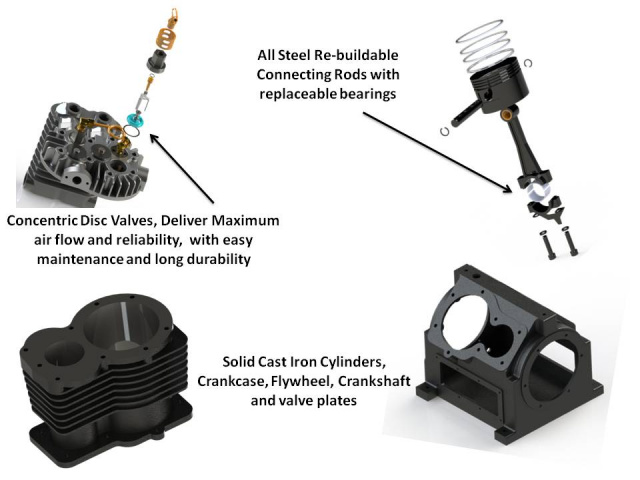

** NEW**PRESSURE LUBE SYSTEM

BLAST CABINET 10 HP Compressor are built to last and are SUPER quiet in operation. This is because of our low pump speeds and compressor design. The Pump has all steel connecting rods with replaceable rod bearing inserts. This means our rods can be rebuilt and are not a throw-away. 99% of our competitions (name brand) are using aluminum throw-away connecting rods with no rebuild able capability. The all cast iron crankshaft with ball bearings on the front and rear of the crankshaft create a smoother operating compressor and less drag and less electric being used. Removable 100% cast iron cylinders. This is more stable under heavy workloads and does not warp from heat like aluminum cylinders with a pressed-in sleeve. Most of our competition are using aluminum cylinders with a pressed-in sleeve. They are only good for 40-50% duty cycle and claim 100% duty cycle. In a year or so, most are replaced because they would not hold up under heavy use. All cast iron cylinder heads – NOT aluminum. Aluminum heads from heat will warp and cause head gasket problems. BLAST CABINET 10 HP Compressor Compressor are Cast iron head is more dependable and will last with trouble free operation. Intake and Exhaust valves are disk valve design. Most of our competition are using reed valves which are throw away and not rebuildable. Disk valves can be serviced in minutes instead of hours like reed valves. Our disk valves come out of the top of the head. Disk valves have been around for over 100 years. Our compression and oil rings are high quality and provide low oil carry over (1-5 pmm). Our pumps are precision ground pistons with tight tolerances for low oil carry over. We also use quality non-absorbent gaskets. This keeps oil seepage from coming off of the pump. This pump has an all cast iron flywheel with built-in fan– NOT aluminum. Aluminum does not give the proper throw when the pump is running. BLAST CABINET 10 HP Compressor Compressor the extra weight of cast iron when running gives the pump more throw on the compression stroke and puts less load on the electric motor. Our crankcase is also all cast iron – NOT aluminum. All cast iron will give stable crankshaft alignment and will handle more work load under heavy load conditions. This pump has built-in intake head unloaders.(If added to the unit add $149.00) These unloaders are built into the intake valve assembly on the compressor head. These unload or open the intake valves under constant run applications such as gas drive and electric units for constant run applications. This feature reduces internal pump heat from compression because the intake valve is held open under unloading cycle. It allows fresh air to come into the cylinder chamber but under compression stroke, the unloader holds the intake valve open allowing the air to blow back out the intake filter. This fresh air absorbs the heat out of the pump under heavy workloads. This pump includes a pre-cooling line that cools the air before it goes into the tank and also includes an all copper main feed line from the pump into the tank. This is copper for durability and not aluminum. We have one of the lowest RPM compressors on the market. This is critical. Many companies are lowering the quality of their product and running high RPM. High RPM causes high noise or db levels, lots of water in your air because the air is much hotter, lots of vibration and harmonic distortion, less belt wear, and most of all – longer pump life. Don’t cheat yourself…go low RPM and a BIG pump. Go Big or go home – you will be glad you did. Compare pump speeds from different manufacturers and you will see we are the lowest RPM. We can still give you high CFM with low RPM because our bore and stroke are larger allowing us to run the pump slower causing less friction and heat buildup. Just remember…speed kills. Our competition is using small pumps that are noisy and high RPM. This is a recipe for pump failure.

Additional information

| Weight | 1000 lbs |

|---|---|

| Dimensions | 49 × 49 × 87 in |