$79.00

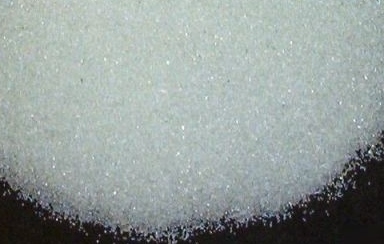

GLASS BEAD (50 lbs.)

Medium 20/40 ~ Fine 40/60

This media is shipped in a double-wall cardboard box enclosed in a .004 mil plastic surrounded by a woven bag to ensure that the product doesn’t leak from the shipping box. This also prevents moisture damage to the media.

Benefits:

We have done a lot of research in media quality and what we have found is most media will say 40/60 and when we did a test the media was actually from 10 to 100 in media size. This causes a different cut with each change of new media. If you have a process like preporation for bonding each change of media will chage the results. Our media will be in the 40/60 size range consistent or send it back for a refund. We have found there is a lot of cheap media in the blasting market.

- BADBOY BLASTERS Glass Bead abrasives are fast-cutting, low-dusting, and tough enough to get the job done

- Aggressive abrasive but leaves a nice finish

- Glass Bead abrasive for general purpose repair or maintenance blasting. Perfect abrasive for paint and/or rust removal. This product hold it’s cutting edge for long blasting life. In a cabinet blaster it can be recycled for many hours of blasting. Plus having very low dust from abrasive making it easier on cabinet blaster air filtration.

- White in color

- Hard, angular particles

- Uniform density

- Silica free

Description

Glass beads are manufactured from lead-free, soda lime-type glass, containing no free silica that is made into preformed ball shapes. Glass beads produce a much smoother and brighter finish than angular abrasives. Glass bead blasting produces a clean, bright, satin finish, without dimensional change of the parts. Glass beads can be recycled approximately 30 times. Chemically inert and environmentally friendly, glass beads are an acceptable method of metal cleaning or surface finishing when properly controlled.

Glass Bead Blasting Applications

Glass bead blasting produces a clean, bright, satin finish, without dimensional change of the parts. Available in a wide range of sizes, glass beads are primarily used in blasting cabinets for honing, polishing, peening, blending, finishing, removing light burrs and cleaning most light foreign matter. For delicate thin-walled parts and thin welds, peening with glass bead abrasive material provides the right balance of stress relief without over-stressing and causing damage. Consider the size of perforations or holes through which the glass beads must pass when screen separating parts from media after use.

As a safety precaution please remember that Silica Sand Abrasive Media can be fatal if inhaled. Please consider this factor prior to using that type of media. Always wear protective breathing equipment when sandblasting.

Additional information

| Weight | 50 lbs |

|---|---|

| Dimensions | 12 × 12 × 6 in |